Why Perforated Sheets Come in Standard Gauges & Thicknesses

At first glance, metal sheet thicknesses may look like random numbers — 0.5 mm, 0.8 mm, 1.2 mm, 1.5 mm, 2 mm… But if you dig deeper, you’ll discover that there’s a fascinating mix of history, tradition, practicality, and global standardization behind why metal sheets are made in these particular thicknesses.

At Sudharsun Perforated Sheets, we’ve worked with fabricators, architects, and industrial clients for decades — and one of the most common curiosities we hear is:

👉 “Why are sheet thicknesses so oddly specific?”

Let’s break it down and uncover why even perforated sheets follow these exact same sizes.

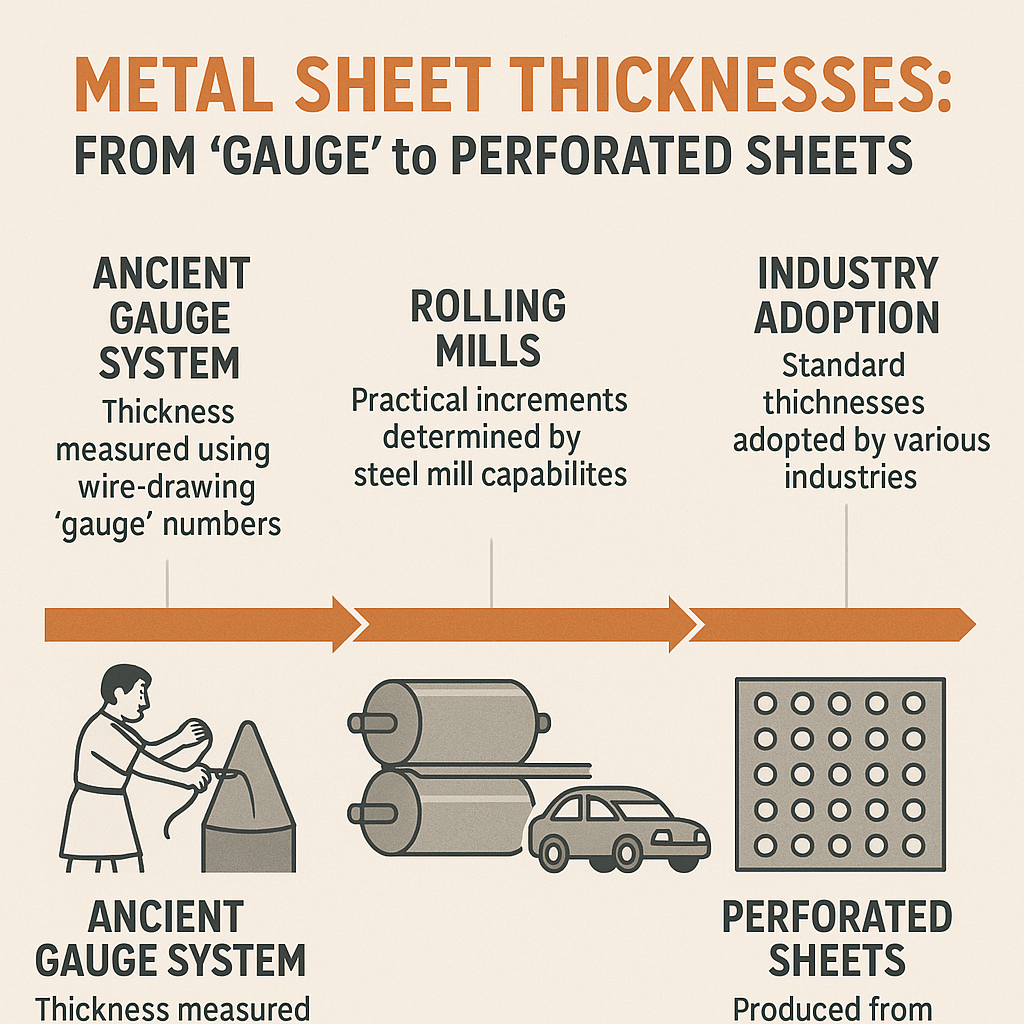

The Old Gauge System: The Origins of Sheet Thickness

Before the world switched to millimeters and micrometers, sheet metal thickness was measured in “gauge” numbers.

Gauge came from wire drawing. Each time a wire was drawn through a die, it got thinner. The more times you pulled it, the higher the gauge number.

That’s why the system feels backwards: a higher gauge means thinner metal. For example:

16 gauge steel ≈ 1.6 mm thick

18 gauge steel ≈ 1.2 mm thickWhen metric systems became the norm, these gauges were simply converted into mm equivalents.

This is why we still have “awkward” decimals like 0.91 mm or 1.22 mm floating around. They’re not mistakes — they’re simply metric versions of old imperial gauges.

👉 Fun fact: The gauge system varies slightly for different metals! For instance, 16 gauge aluminium is not exactly the same thickness as 16 gauge steel.

Manufacturing Practicality: What Steel Mills Could Produce

Rolling a massive steel ingot into thin sheets isn’t just about precision — it’s about what’s practical for the machines.

Historically, rolling mills could only reduce thickness in specific increments.

Producing sheets in clean steps like 0.5 mm, 0.8 mm, 1.0 mm, 1.2 mm, 1.5 mm, 2.0 mm was easier, faster, and less wasteful.

These standard increments also simplified tooling, cutting, welding, and punching.

That’s why we rarely see “in-between” thicknesses like 1.3 mm or 1.7 mm — they just don’t align with mill capabilities and tooling efficiency.

👉 In short, the numbers we use today were shaped by the limitations and efficiency of early rolling technology.

Industry Adoption: Sizes That Worked Best

Over time, industries began to settle on thicknesses that were “just right” for their needs.

0.45–1.2 mm sheets → popular in roofing, ducting, and lightweight structures (strong yet flexible).

1.5–3 mm sheets → widely used in automotive body panels, architectural cladding, and machinery covers (a balance of rigidity and formability).

5 mm and above → reserved for heavy-duty applications like shipbuilding, construction, and industrial machinery.

Once these thicknesses became the “sweet spot” for applications, they turned into industry standards — and eventually became global norms.

Global Standardization: From Local to International

To make global trade smooth, organizations like ASTM (USA), IS (India), JIS (Japan), and BS (UK) stepped in to formalize thickness ranges.

This standardization brought big advantages:

Compatibility → A 1.5 mm sheet in India is the same as in the US or Japan.

Simplified Tooling → Die makers, perforation manufacturers, and welders could design around fixed sizes.

Efficient Supply Chains → No confusion in international orders, making sheet trade seamless.

👉 In short: standard thickness = global consistency.

Why Perforated Sheets Follow the Same Rule

Now let’s connect this history to what we do at Sudharsun Perforated Sheets.

Perforated sheets are produced by punching holes or designs into base metal sheets. Since those base sheets are only manufactured in standard gauges, perforated sheets are also limited to the same.

That’s why you’ll always see perforated sheets offered in:

0.5 mm, 0.8 mm, 1.0 mm, 1.2 mm, 1.5 mm, 2 mm, etc.

Whether you’re using micro-perforated sheets (as thin as 0.5 mm for filtration) or thicker decorative panels (up to 3 mm for architecture), the sizes always trace back to the standard rolling thicknesses of sheet metal.

Why This Still Matters Today

Even with CNC machines and advanced production, the world sticks to these thicknesses because:

They ensure global compatibility.

They keep costs under control — no special dies or tools needed for odd sizes.

They maintain uniform supply chains — ensuring sheets and perforated sheets are always interchangeable.

👉 Next time you order a 1.5 mm perforated sheet, you’re not just buying a piece of metal. You’re holding a piece of industrial history and global standardization in your hands.

FAQs: Perforated Sheets Standard Gauges

What is 16 gauge sheet in mm?

For carbon steel, 16 gauge is approximately 1.6 mm. Exact values vary slightly by standard, so always confirm the gauge-to-mm table for your material.

Why do perforated sheets follow standard gauges?

Perforated sheets are punched from base metal sheets that are produced in standard gauges. To keep tooling, supply chains, and performance consistent worldwide, perforated sheets standard gauges mirror those base-sheet sizes.

Why aren’t sizes like 1.3 mm or 1.7 mm common?

Rolling mills historically reduced thickness in practical steps (e.g., 0.5, 0.8, 1.0, 1.2, 1.5, 2.0 mm). Non-standard thicknesses raise cost, complicate tooling, and are rarely stocked.

Do gauge numbers match across metals?

No. A “16 gauge” aluminium sheet is not the same thickness as “16 gauge” steel. Use a material-specific gauge-to-mm conversion chart.

What’s the thinnest perforated sheet commonly available?

Micro-perforated options often start around 0.5 mm (material- and application-dependent), with patterns chosen to maintain strength and open area.

Final Thoughts

Sheet thicknesses are not random at all — they’re the result of centuries of tradition, the old gauge system, manufacturing practicality, and international standardization.

And because perforated sheets begin as these same rolled sheets, they naturally follow the exact same thickness ranges.

At Sudharsun Perforated Sheets, we manufacture and supply MS, SS, GI, Aluminium, and Non-Ferrous perforated sheets across all standard gauges. Whether you’re building, filtering, designing, or fabricating — our sheets are backed by global standards and industry trust.

✨ So, the next time someone asks you “Why is sheet metal 1.2 mm and not 1.3 mm?” — you’ve got the story, the science, and the history to answer it!