Transforming Stamping Platform with MS Diamond Perforated Sheet

Introduction

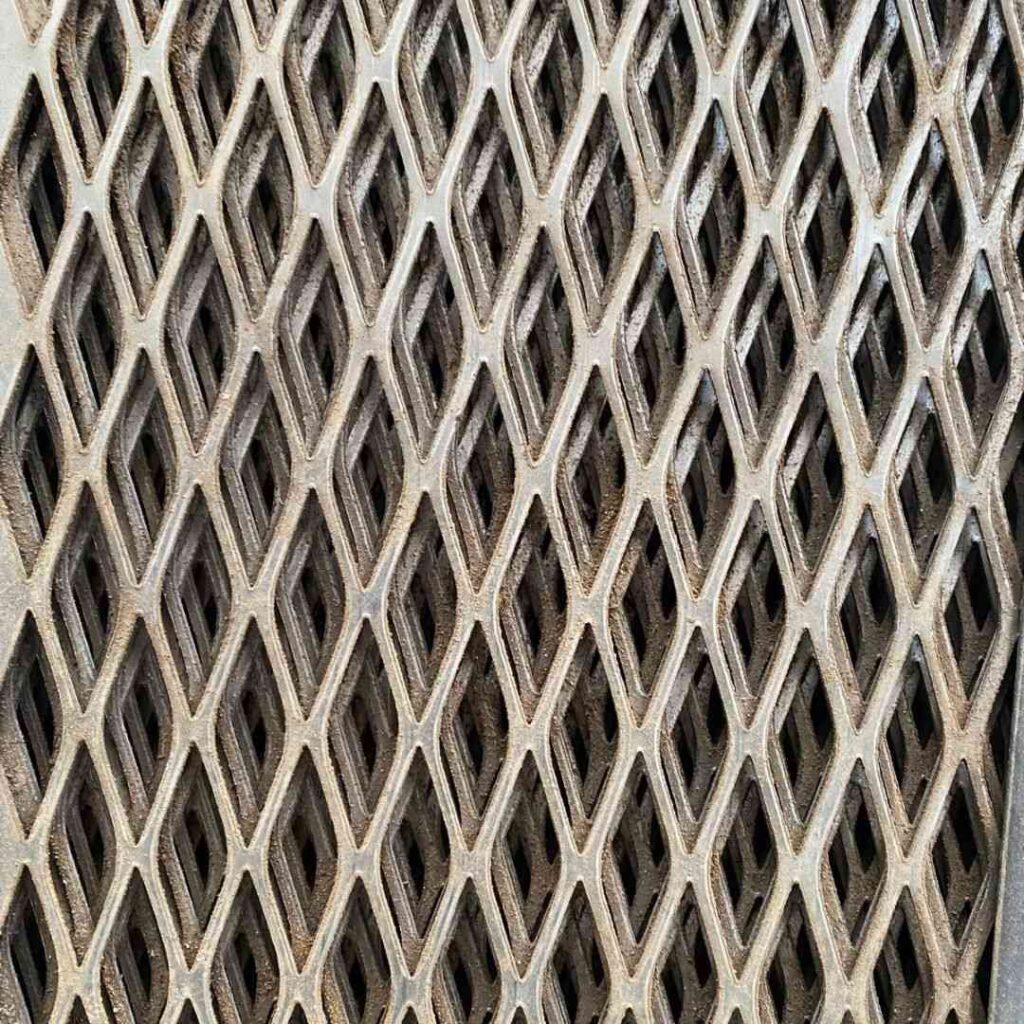

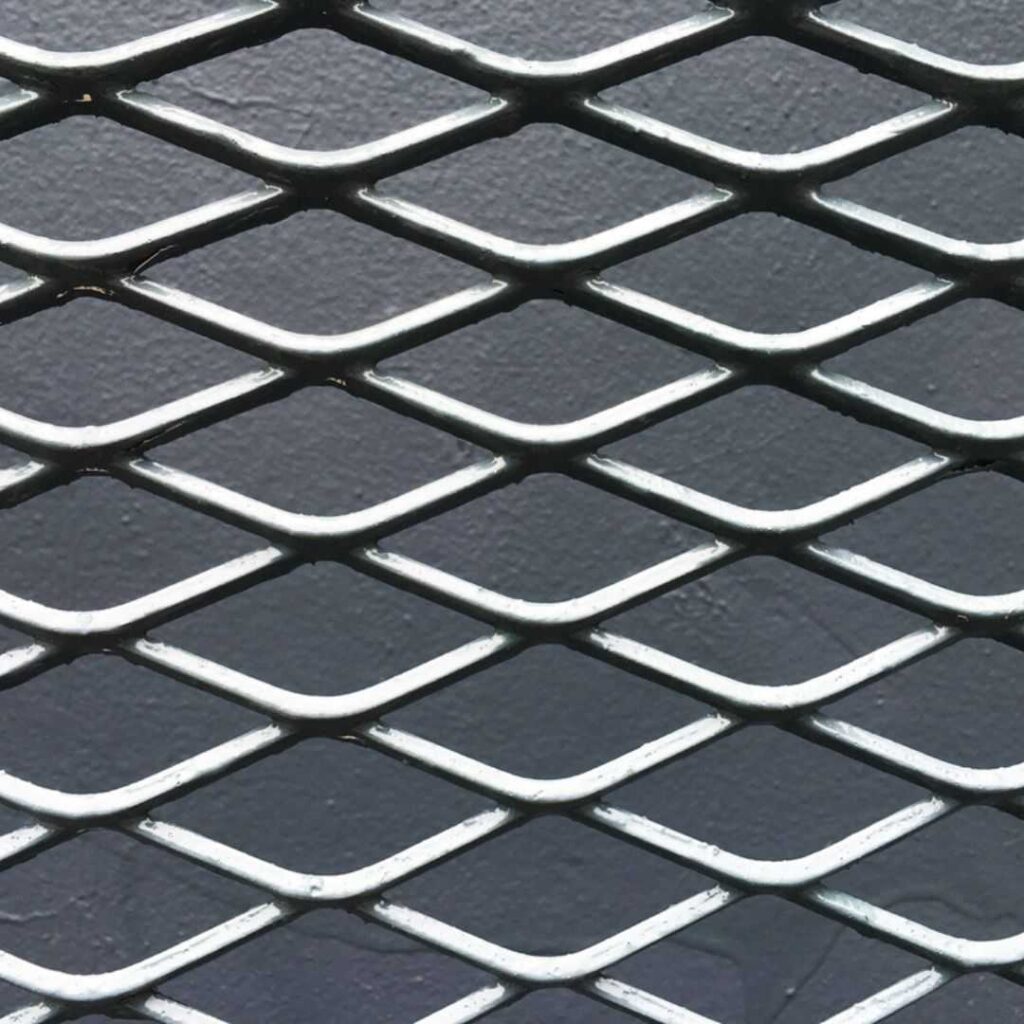

Our client, a leading manufacturing company, faced a unique challenge: they needed a specialized tool for stamping platform plywood. The tool had to be precise, durable, and heat-resistant. The existing alternative—a diamond mesh—had sharp edges and twisted sheet bridges, compromising the plywood’s integrity during stamping. Our team took on the project, and the results were remarkable.

Client Requirements

- Specific Diamond Pattern:

- The client required a perforated metal sheet with a specific diamond pattern. This pattern was crucial for efficient stamping and consistent results.

- Sheet Thickness:

- The sheet needed to be of a specific thickness to withstand the stamping process without warping or deforming.

- Heat Resistance:

- The die would be heated during the stamping process. Therefore, the material had to withstand high temperatures without compromising its structural integrity.

Our Approach

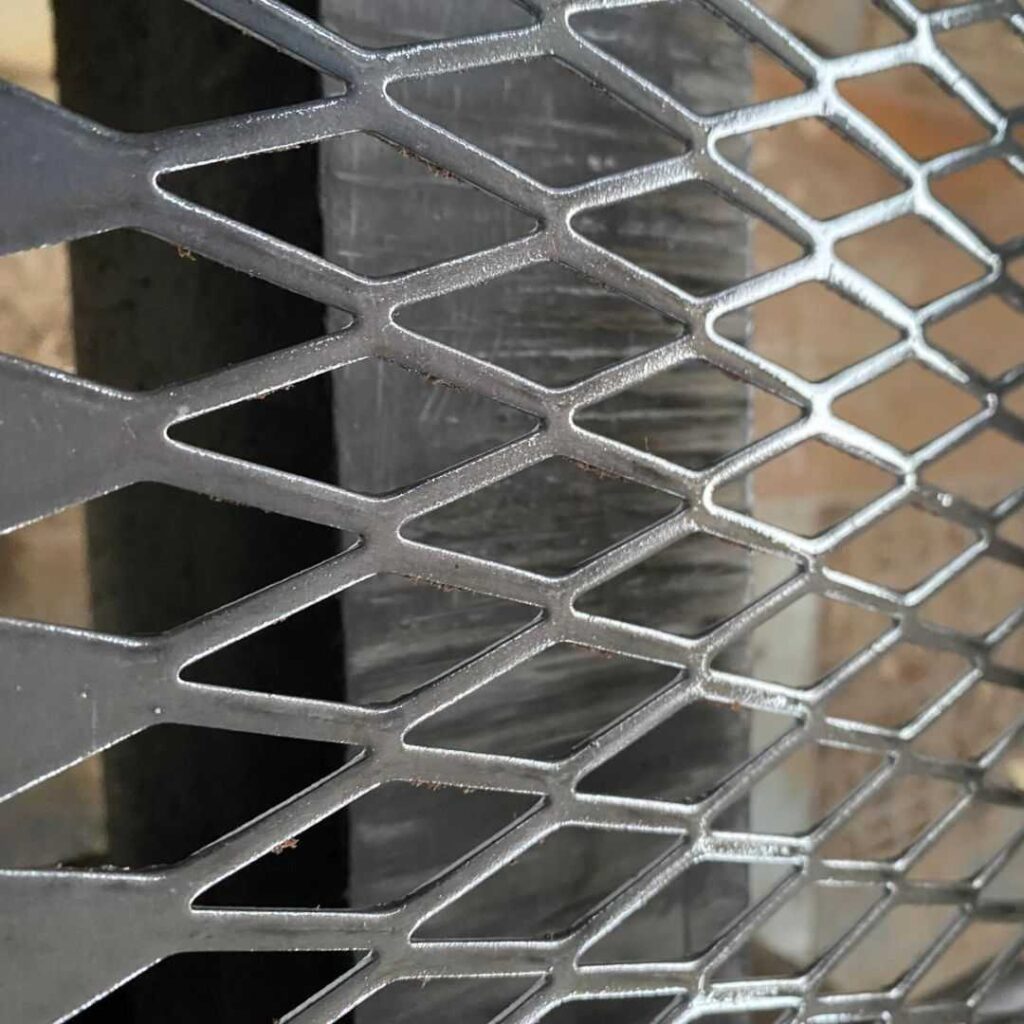

- Material Selection:

- We recommended mild steel (MS) perforated sheets due to their strength, versatility, cost-effectiveness and ease of fabrication.

- The diamond pattern was precisely punched into the sheet using advanced machinery.

- Optimized Design:

- Our engineers fine-tuned the diamond pattern to ensure optimal strength and uniformity using CNC EDM.

- We adjusted the hole size and pitch spacing to balance structural integrity and functionality.

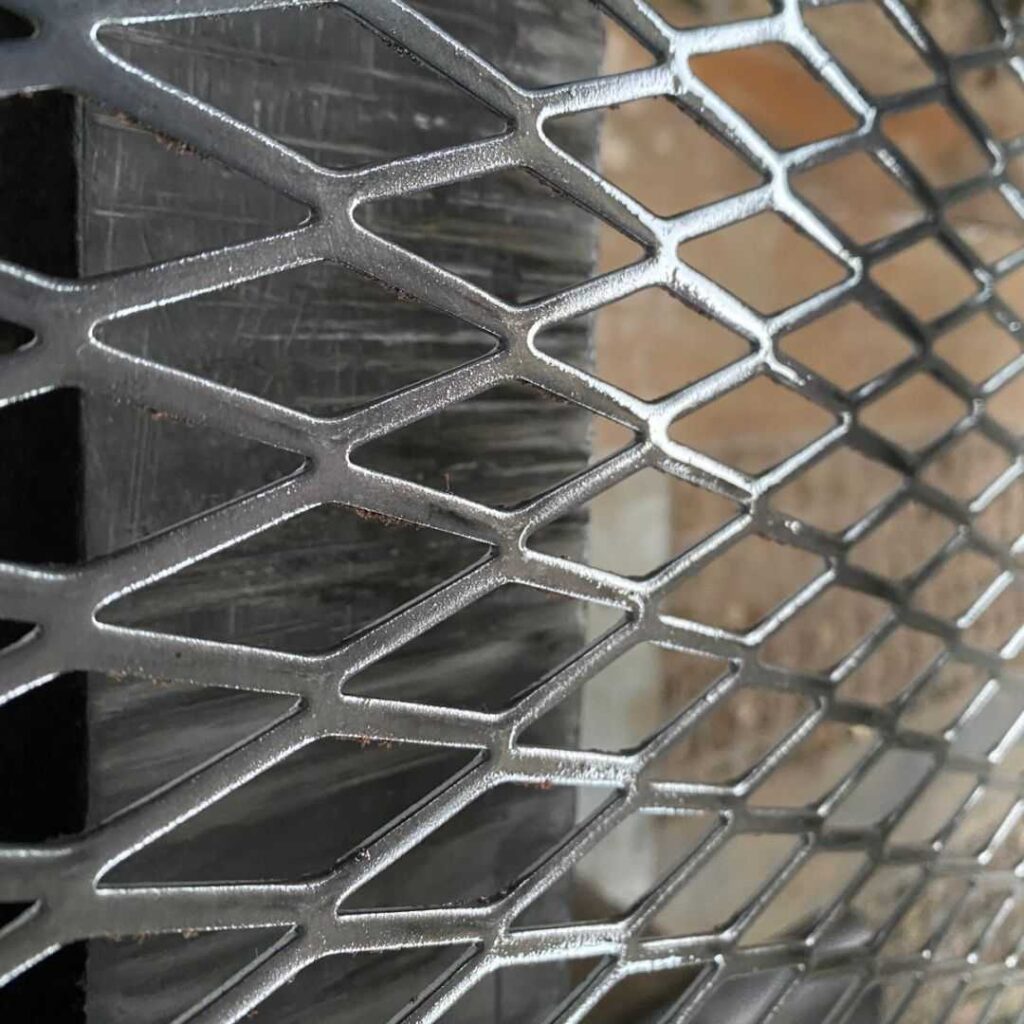

- Heat-Resistant Coating:

- To enhance heat resistance, we applied a specialized coating to the perforated sheet.

- This coating protected the tool during the stamping process, preventing warping or damage.

Results

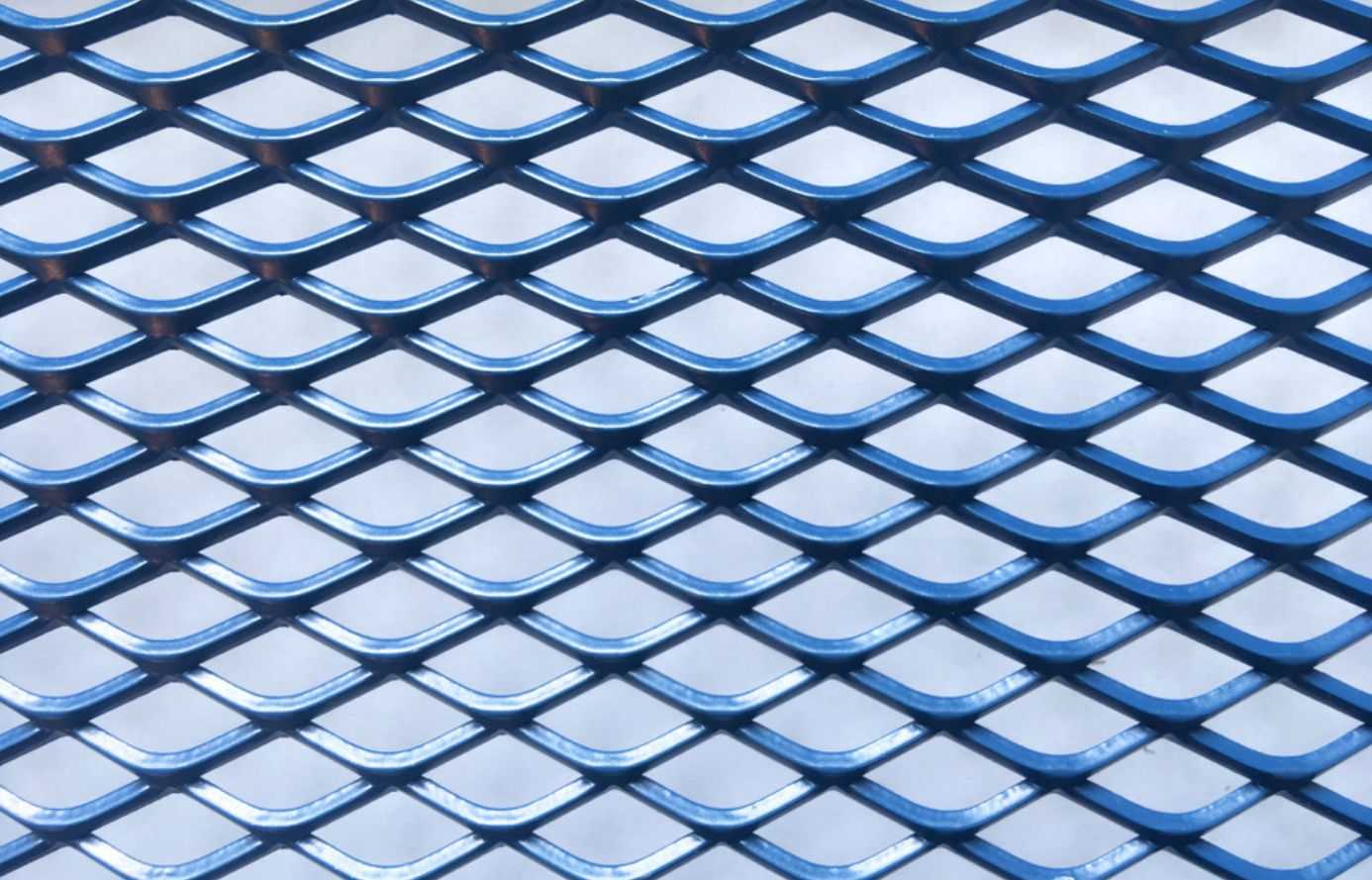

- Stunning Mesh:

- The MS perforated sheet transformed into a stunning mesh, precisely matching the desired diamond pattern.

- Its clean edges and uniform holes ensured flawless stamping results.

- Improved Plywood Integrity:

- Unlike the diamond mesh alternative, our perforated sheet had smooth edges and no twisted bridges.

- This safeguarded the plywood’s integrity, preventing splintering or surface damage.

- Efficient Stamping:

- The optimized design allowed for efficient material flow during stamping.

- The tool performed consistently, reducing production time and minimizing waste.

Conclusion

Our team’s expertise in material, design, tool development and fabrication led to a successful outcome. The MS perforated sheet not only met but exceeded the client’s expectations. By choosing the right material, optimizing the design, and ensuring heat resistance, we delivered a game-changing solution for their stamping platform. 🛠️🔥🔍