The Versatility and Practicality of Perforated Sheets: Exploring Their Many Applications and Benefits

Understanding the Basics of Perforated Sheets and How They are Manufactured

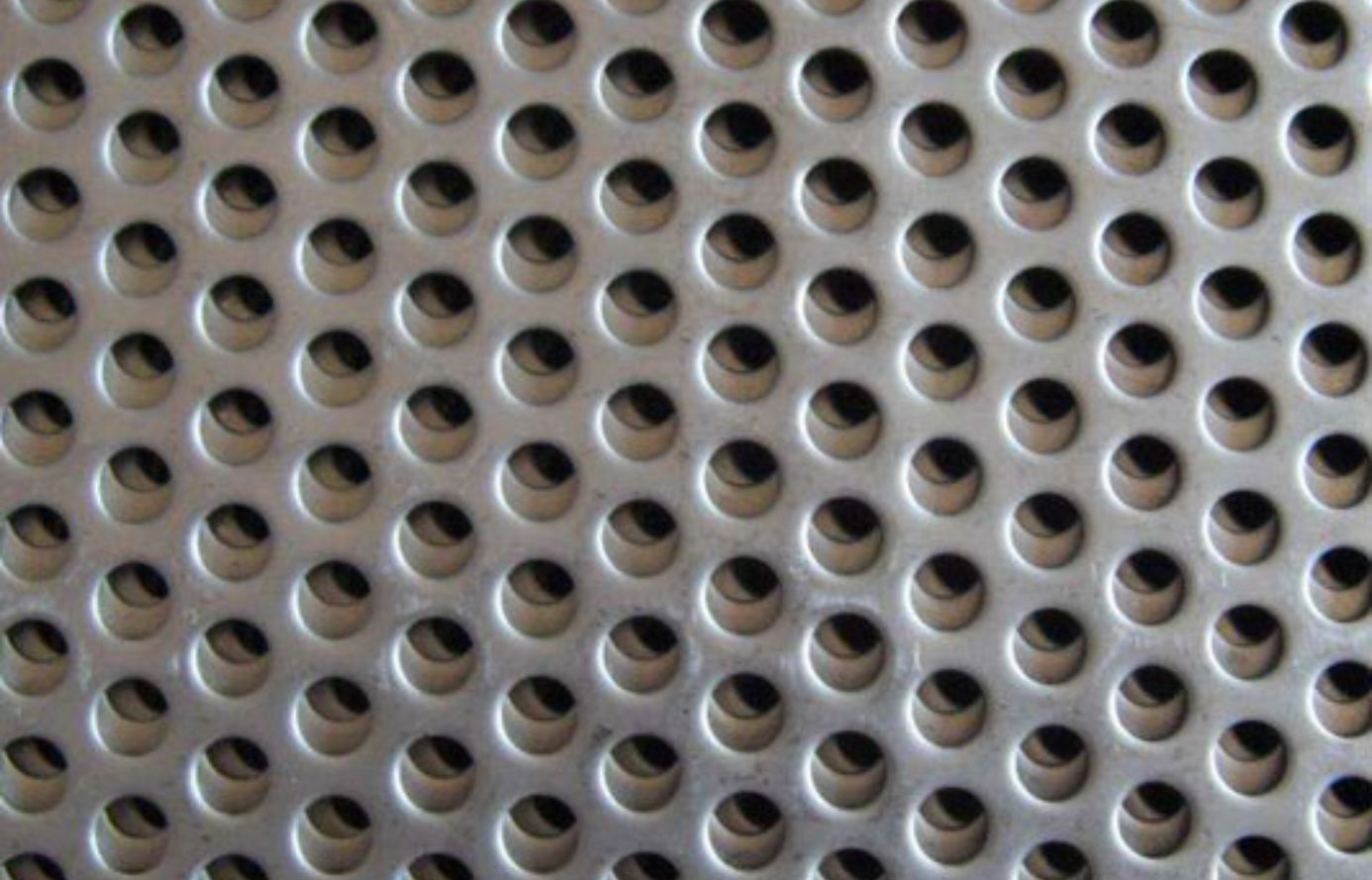

Perforated sheets play a crucial role in various industries, offering versatility in design and functionality. Typically made through sheet metal fabrication, the process involves metal punching to create precise perforation patterns. These patterns can vary, influencing factors like ventilation, filtration, or aesthetics. Perforated plate manufacturing employs techniques such as laser cutting or CNC punching to achieve accuracy. The result is a durable and efficient material suitable for applications ranging from architectural elements to industrial filters. Understanding these basics helps us appreciate the ingenuity behind perforated sheets and their diverse uses.

The Wide Range of Applications for Perforated Sheets in Various Industries?

Perforated sheets find a myriad of applications across industries due to their adaptability. In architecture, they serve as dynamic design elements, enhancing facades or creating striking visual effects. In filtration systems, perforated sheets facilitate efficient particle separation. Acoustic panels benefit from their sound-absorbing properties, enhancing acoustic performance in spaces. Ventilation systems leverage perforated sheets for optimal airflow control. Beyond functionality, these sheets are embraced for decorative purposes, adding a touch of style to diverse settings. From modern building aesthetics to essential industrial functions, the versatility of perforated sheets makes them indispensable across architectural, filtration, acoustic, ventilation, and decorative applications.

Tips on Choosing the Right Material and Thickness for Your Perforated Sheet Needs

Choosing the right material and thickness for your perforated sheet is crucial for optimal performance. Stainless steel perforated sheets offer durability and corrosion resistance, making them ideal for harsh environments. Aluminum perforated sheets are lightweight and corrosion-resistant, suitable for applications where weight is a concern. Galvanized steel perforated sheets provide added protection against rust. Consider the specific requirements of your project and the environmental conditions it will face. The thickness of the sheet influences its strength, with thicker sheets offering greater durability. Assess the load-bearing needs and intended application to determine the appropriate material and thickness for your perforated sheet requirements.

Maintaining and Caring for Your Perforated Sheet to Ensure Longevity and Optimal Performance

Ensuring the longevity and optimal performance of your perforated sheet involves adopting effective maintenance practices. Regular cleaning is essential, and using non-abrasive methods helps preserve the integrity of the perforations. Corrosion prevention measures, such as applying protective coatings or choosing corrosion-resistant materials like stainless steel, are vital for durability. Inspect the sheets periodically for signs of wear or corrosion, addressing any issues promptly to prevent further damage. By incorporating these cleaning tips and corrosion prevention measures into your maintenance routine, you can extend the lifespan of your perforated sheets, ensuring they continue to perform at their best over the long term.