The Evolutionary Impact of Wire Mesh in the Manufacturing Sector.

Introduction:

In the dynamic landscape of manufacturing, where precision, durability, and efficiency reign supreme, wire mesh emerges as a silent powerhouse. From providing structural support to enhancing safety measures, wire mesh has become an indispensable component across various sectors within the manufacturing industry.

Properties and Types of Wire Mesh:

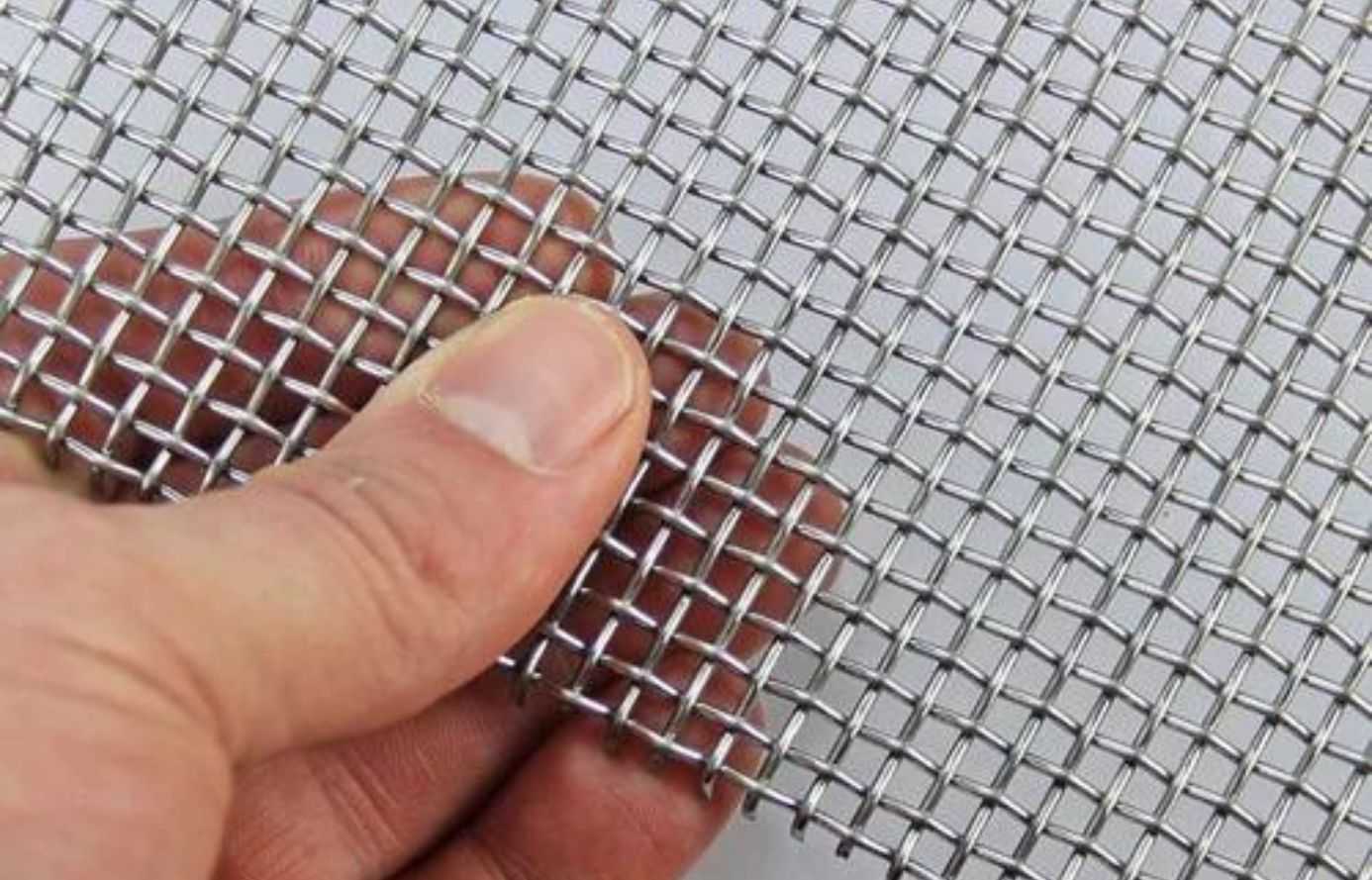

Dive into the inherent properties of wire mesh, emphasizing its strength, flexibility, and versatility. Explore the different types of wire mesh—woven, welded, and expanded—and their specific applications in the manufacturing realm.

Reinforcement in Industrial Processes:

In manufacturing, where heavy machinery and structural stability are paramount, wire mesh serves as a reinforcement material. From reinforcing concrete structures to providing support in the construction of industrial facilities, wire mesh plays a pivotal role in ensuring the structural integrity of manufacturing environments.

Machine Guarding and Safety Applications:

Safety is a top priority in manufacturing, and wire mesh serves as a crucial element in machine guarding. Explore how wire mesh panels and enclosures provide a protective barrier without compromising visibility. This application ensures the safety of workers while allowing for efficient monitoring of machinery.

Conveyor Belt Systems:

Conveyor belt systems are the lifelines of manufacturing plants. Wire mesh belts, with their durability and efficient heat dissipation properties, find extensive use in conveying products through various stages of the manufacturing process. Dive into the applications and benefits of wire mesh in conveyor systems.

Filtration and Separation Processes:

The manufacturing industry often involves processes that require precise filtration and separation. Wire mesh screens and filters are integral components in ensuring the quality and purity of products, ranging from pharmaceuticals to food processing.

Custom Solutions for Manufacturing Challenges:

Highlight the adaptability of wire mesh in addressing specific challenges faced by manufacturers. From creating custom mesh patterns to designing solutions for unique manufacturing processes, wire mesh offers tailor-made answers to complex problems.

Case Studies:

Examine real-world examples of manufacturers who have successfully integrated wire mesh into their processes. Showcase instances where wire mesh has been a transformative factor, improving efficiency, reducing costs, and enhancing overall production quality.

Innovations in Wire Mesh Technology:

Explore the cutting-edge innovations in wire mesh technology, such as the use of advanced materials, smart monitoring systems, and 3D-printed mesh structures. Discuss how these innovations are pushing the boundaries of what wire mesh can achieve in the manufacturing sector.

Challenges and Solutions:

Acknowledge the challenges manufacturers may face in implementing wire mesh solutions, such as corrosion in harsh environments or the need for specific material properties. Present solutions and best practices to overcome these challenges effectively.

Future Trends in Wire Mesh Integration:

Look ahead to the future of wire mesh in manufacturing. Discuss emerging trends, such as the integration of artificial intelligence for predictive maintenance or the use of nanotechnology in creating advanced wire mesh materials.

Conclusion:

As the manufacturing industry continues to evolve, wire mesh stands as a testament to the synergy of innovation and practicality. Its transformative role in reinforcing structures, ensuring safety, and optimizing processes makes it an unsung hero in the manufacturing landscape, quietly contributing to the efficiency and progress of diverse manufacturing sectors.