Optimizing Air Pressure with Custom Perforated Metal Sheets

Introduction

At Sudharsun Perforated Sheets, we pride ourselves on delivering tailored solutions to our clients. Recently, we had the opportunity to collaborate with customer-facing air pressure challenges within their machinery. Their existing perforated metal sheet, with standard hole diameter and staggered pitch, was causing significant issues. Our mission was clear: design a custom perforated metal sheet that would optimize air pressure and enhance overall machine performance.

Client Background

Our client, a leading industrial manufacturer, relied on precision machinery for their production processes. However, inconsistent air pressure disrupted their operations, affecting output quality and efficiency. They needed a specialized solution to address this critical issue.

Problem Statement

The existing perforated metal sheet led to irregular airflow patterns, resulting in suboptimal air pressure within the machine. Our challenge was to create a customized sheet that would improve airflow while maintaining structural integrity.

Solution

- Collaborative Analysis: We closely collaborated with the client’s engineering team to understand their specific requirements. Through simulations and parameter adjustments, we identified the optimal hole diameter and bridge gap dimensions.

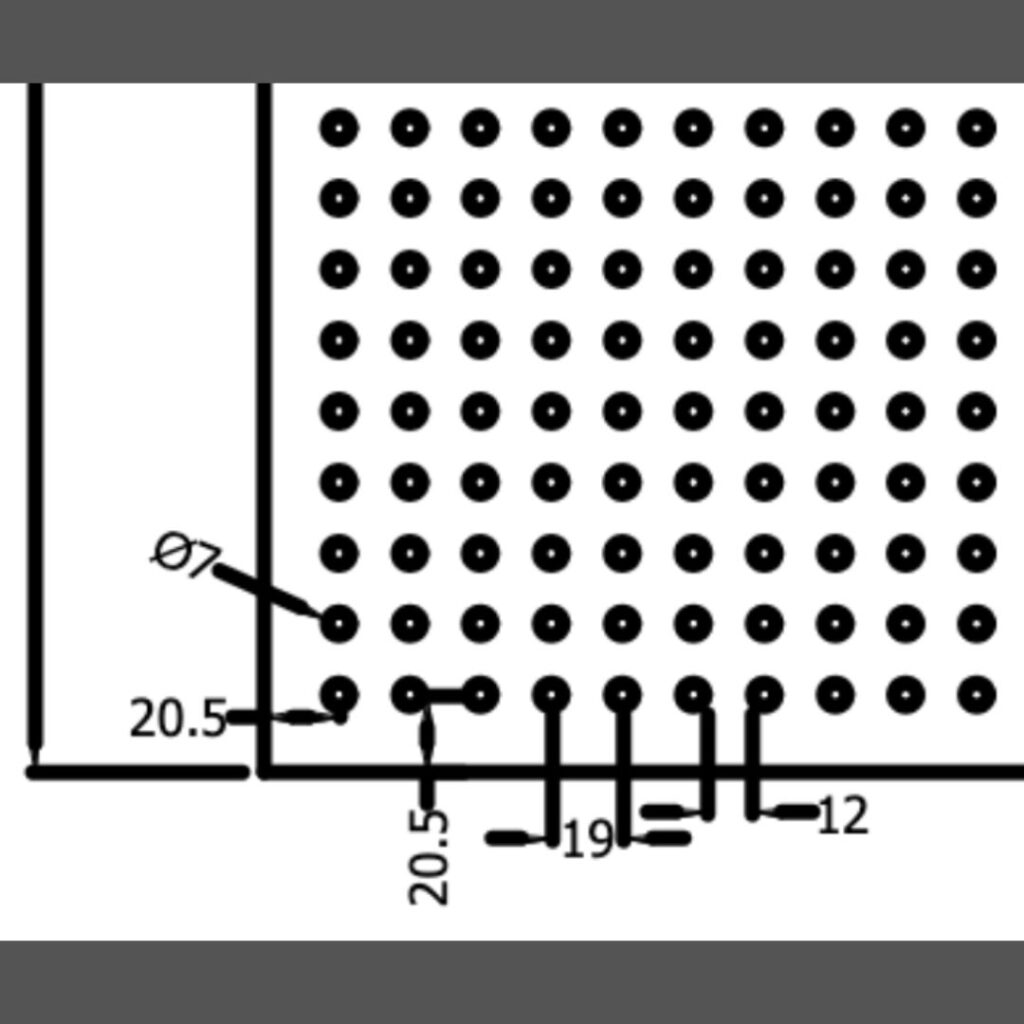

- Custom Design: Based on the client’s insights, we designed a perforated metal sheet with the following specifications:

- Hole Diameters: 3.20mm, 5mm, and 7mm

- Bridge Gap: 12mm between each hole

- Staggered arrangement for uniform airflow

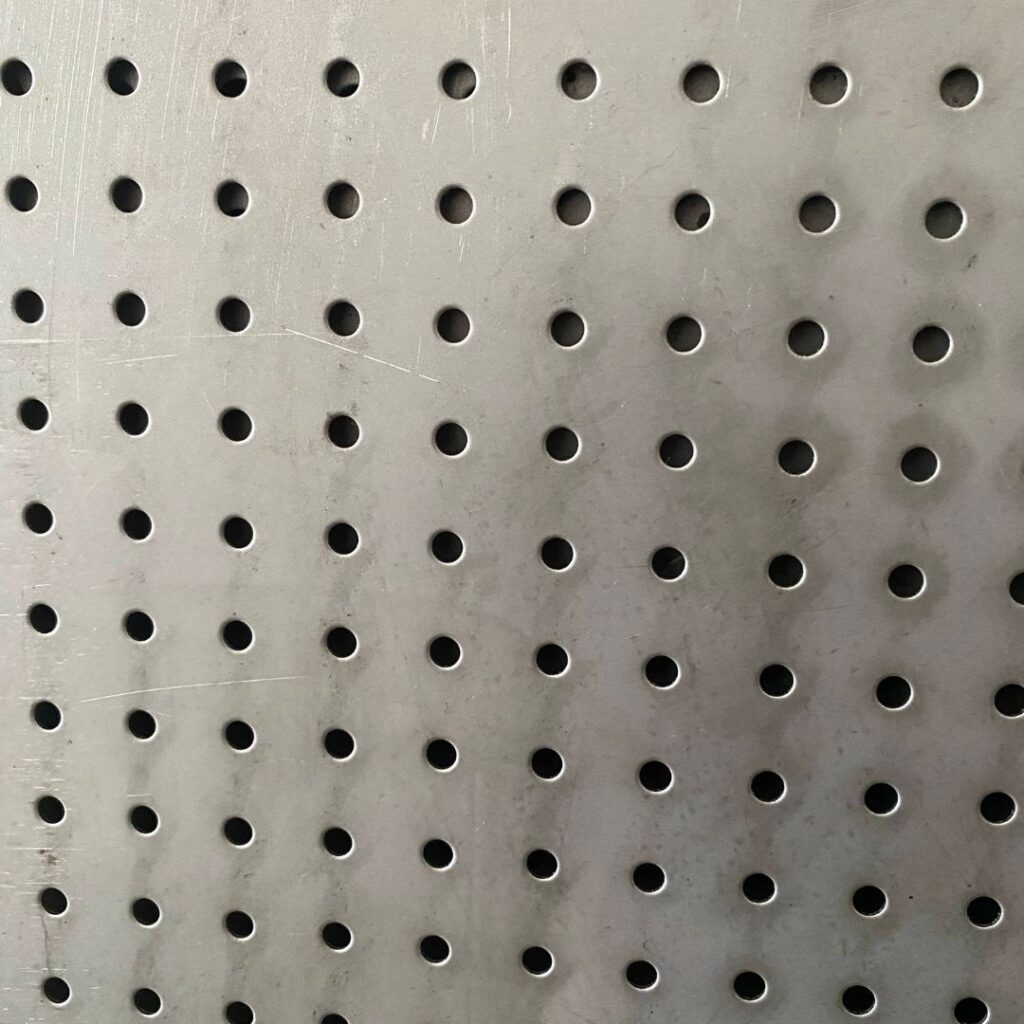

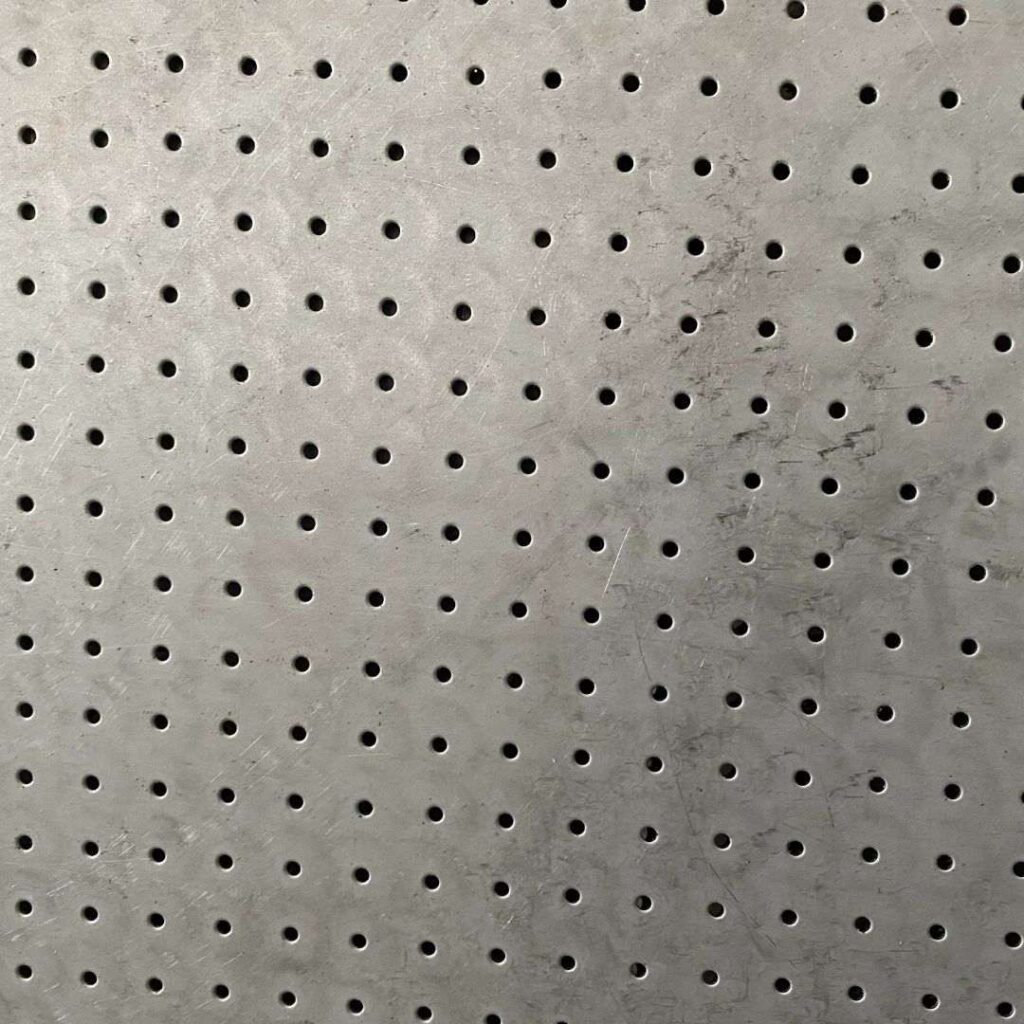

- Precision Manufacturing: Our skilled craftsmen meticulously fabricated the custom sheet, ensuring precise hole placement and consistent dimensions.

- Installation and Testing: We installed the new perforated metal sheet in the client’s machinery. Rigorous testing confirmed that the airflow was now optimized, resulting in stable air pressure levels.

Results

The impact of our custom solution was remarkable:

- Stable Air Pressure: The machine now maintained consistent air pressure, leading to improved production efficiency.

- Enhanced Output Quality: With optimal airflow, the final product quality met industry standards.

- Client Satisfaction: Our client expressed their satisfaction with the seamless execution and tangible results.

Conclusion

Our successful collaboration with this client exemplifies Sudharsun Perforated Sheet’s commitment to innovation and problem-solving. If you’re facing similar challenges, reach out to us for customized solutions that deliver real impact.