Comparing Perforated Metal and Expanded Metal: A Comprehensive Guide

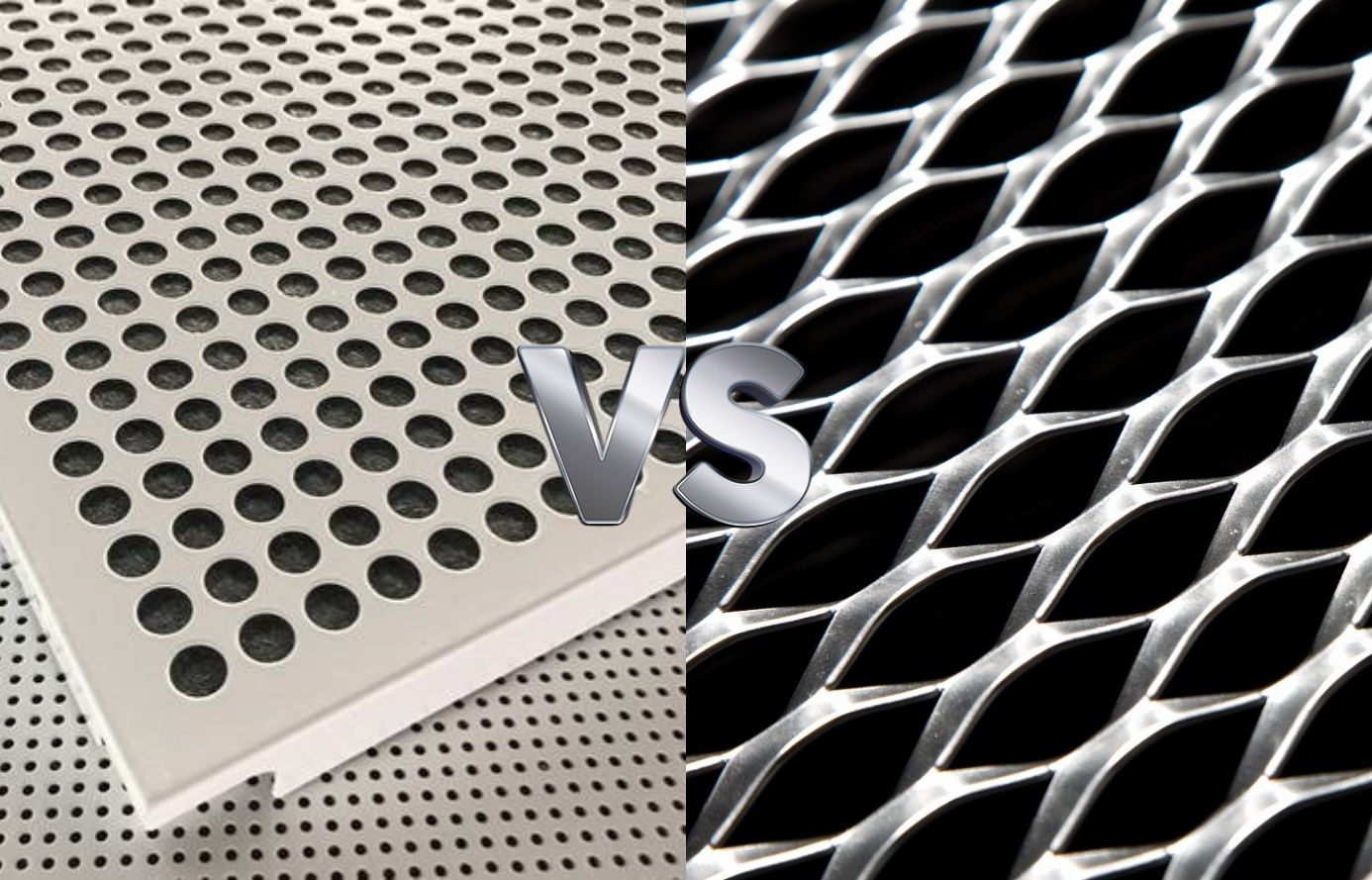

Perforated Metal vs. Expanded Metal: A Quick Guide

Perforated metal and expanded metal are two distinct types of metal sheets with different characteristics, applications, and manufacturing processes. Here’s a comparison between perforated metal and expanded metal based on key factors:

- Manufacturing Process:

- Perforated Metal: Created by punching holes into a flat metal sheet using a die. This process allows for precise patterns and hole shapes, offering design flexibility.

- Expanded Metal: Produced by cutting and stretching a metal sheet, creating a pattern of interconnected openings. The stretching process gives expanded metal its distinctive diamond-shaped pattern.

- Open Area and Airflow:

- Perforated Metal: Provides a controlled open area based on the pattern and density of the holes. This allows for customization in airflow and light diffusion.

- Expanded Metal: Typically has a higher open area compared to perforated metal, allowing for increased airflow and visibility through the mesh.

- Strength and Rigidity:

- Perforated Metal: Generally maintains more structural integrity and rigidity due to the base metal and the fact that only a portion of the material is removed.

- Expanded Metal: Exhibits strength and rigidity due to the interconnected strands formed during the expanding process. It is often used for structural applications.

- Material Usage:

- Perforated Metal: Suitable for a wide range of materials, including stainless steel, aluminum, carbon steel, and others. Material choice depends on factors such as corrosion resistance, strength, and appearance.

- Expanded Metal: Commonly available in materials like carbon steel, aluminum, and stainless steel, with variations in thickness and strand width.

- Applications:

- Perforated Metal: Used in diverse applications such as architectural design, filtration, acoustics, and decorative elements. It is ideal for projects requiring precision and customization.

- Expanded Metal: Applied in fencing, walkways, platforms, grating, and security applications due to its strength and versatility. It is suitable for projects where structural support is important.

- Cost Considerations:

- Perforated Metal: The manufacturing process and precision punching can contribute to higher production costs, but it offers intricate design possibilities.

- Expanded Metal: Generally more cost-effective due to the simpler manufacturing process, making it a practical choice for certain applications.

- Aesthetics:

- Perforated Metal: Known for its visually appealing patterns, offering designers creative freedom for decorative and architectural purposes.

- Expanded Metal: Features a distinctive diamond-shaped pattern, which may be less intricate but provides a modern and industrial aesthetic suitable for various applications.